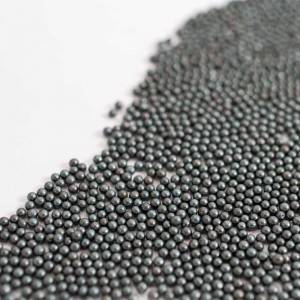

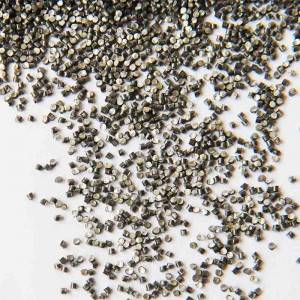

High Carbon Rounded Steel txhaj tshuaj

Qauv / Loj:S110-S930 / Φ0.3mm-2.8mm

Product Detail:

High carbon steel tua, ua los ntawm cov hlau tshwj xeeb, hardened thiab tempered, muaj cov ntsiab lus ntawm cov pa roj carbon ntau dua 0.85% los ntawm cov txheej txheem atomization, kheej kheej cov khoom ua los ntawm cov hlau molten.Fengerda nruj me ntsis tswj txhua qhov txuas ntawm kev tsim khoom, tshwj xeeb tshaj yog kev tswj ntawm deoxidation thiab decarbonization, kub hauv cov txheej txheem quenching, nrog rau kev tshem tawm cov pores thiab txawv txav tom qab tsim, uas txhim kho cov khoom mus rau qib tshiab.

Cov ntsiab lus tseem ceeb:

| PROJECT | SPECIFICATION | KEV TIV THAIV | |||

| CHEMICAL COMPOSITION |

| 0.8-1.2% | P | ≤ 0.05% | ISO 9556: 1989 Daim Ntawv Pov Thawj TS EN ISO 439: 1982 TS EN ISO 629: 1982 TS EN ISO 10714: 1992 |

| Si | ≥0.4% | Cr | / | ||

| Mn | 0.35-1.2% | Mo | / | ||

| S | ≤ 0.05% | Ni | / | ||

| MICROTRUCTURE | Homogeneous Martensite los yog Bainite | GB/T 19816.5-2005 | |||

| Qhov ntom | ≥7.0 * 10³kg / m³ (7.0kg / dm³) | GB/T 19816.4-2005 | |||

| EXTERNALFORM | Cua qhov <10%.Conjoins.Lub kaum ntse ntse.Deformity tus nqi <10% | Pom kev | |||

| HARDNESS | HV: 390-530 (HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Cov kauj ruam ua:

Qhov zoo:

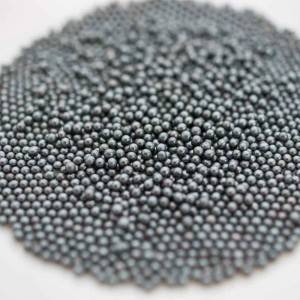

High Carbon Rounded Steel Shot siv cov txheej txheem tsim khoom ib txwm siv, siv rau kev tu thiab tua peening mas.Perfectly tswj cov kev kho cua sov muab nws nrog optimum resilience thiab tiv taus qaug zog.

thiab ua kom tiav cov hlau uas yuav tsum tau muaj zog hnav thiab qaug zog.Nyob rau hauv tus txheej txheem, txhaj tshuaj bombards cov hlau ib feem, tsim me me dimples nyob rau saum npoo.

Cov dimples ua rau compression stresses nyob rau saum npoo ntawm ib feem, ua rau cov hlau tsis kam mus tawg, qaug zog, thiab corrosion.Kev txhaj tshuaj peening yog siv rau cov khoom tseem ceeb, siab hnav xws li iav, ncej thiab cov tawv nqaij hlau rau cov khoom siv aerodynamic siab heev.

Daim ntawv thov:

Peb cov roj carbon siab txhaj tshuaj yog siv ntau yam kev siv xws li;desanding, descaling, tu, tua peening thiab lwm yam.. Cov txheej txheem centrifugal atomization thiab ob chav kho cua sov ntawm cov nroj tsuag Airblast, nrog rau kev tswj xyuas zoo, ua kom cov tshuaj tua tau zoo tshaj plaws.

Nto moj tej tawg tu ntawm forgings, heattreated pieces, steel kav, seem thiab steel lug, nto kho ua ntej pleev xim, tua peening ntawm ua hauj lwm daim.

Nto moj tej tawg ntxuav ntawm stainless hlau daim hlau, nyias hlau daim hlau, tsis ferrous alloys, dacromet coat.