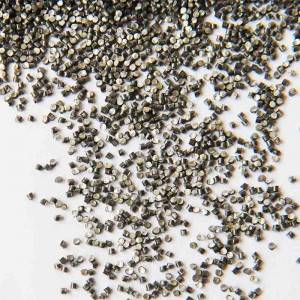

Tsawg Carbon Angular Steel Grit

Cov ntsiab lus tseem ceeb:

| PROJECT | SPECIFICATION | KEV TIV THAIV | |||

| CHEMICAL COMPOSITION | C | 0.08-0.2% | P | ≤ 0.05% | ISO 9556: 1989 Daim Ntawv Pov Thawj TS EN ISO 439: 1982 TS EN ISO 629: 1982 TS EN ISO 10714: 1992 |

|

| Si | 0.1-2.0% | Cr | / |

|

|

| Mn | 0.35-1.5% | Mo | / |

|

|

| S | ≤ 0.05% | Ni | / |

|

| MICROTRUCTURE | Homogeneous Martensite los yog Bainite | GB/T 19816.5-2005 | |||

| Qhov ntom | ≥7.0-10³kg/m³ (7.0kg/dm³) | GB/T 19816.4-2005 | |||

| EXTERNALFORM | Etched los yog angular nto profile, Cua qhov <10%. | Pom kev | |||

| HARDNESS | HV: 390-530 (HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Cov kauj ruam ua:

Khawb → Xaiv & Txiav → Melting → Refine (decarbonize) → Atomizing → Qhuav → Scalper Screening → Spiralizing & Tshuab kom tshem tawm cov cua qhov → Thawj quenching → Qhuav → Derusting → Qhov thib ob tempering → Txias → tawg → Fine ntsuam xyuas → Packing & Warehousing

QHOV CARBON STEEL GRANAL ADVANTAGE Tus Nqi

• Kev ua tau zoo tshaj 20% tiv thaiv cov pa roj carbon ntau

• Tsawg hnav ntawm cov tshuab thiab cov cuab yeej siv vim qhov nqus ntawm lub zog ntau dua hauv cov kev cuam tshuam hauv cov khoom

• Cov khoom tsis muaj qhov tsis xws luag tsim los ntawm kev kho cua sov, pob txha tawg lossis micro tawg

Txhim kho ib puag ncig

• txo cov hmoov nplej

• Bainitic microstructure lav tias lawv yuav tsis tawg thaum lub sijhawm nws lub neej muaj txiaj ntsig

HEEV HEEV

Cov duab ntawm qhov qis carbon steel txhaj tshuaj zoo ib yam li spherical.Qhov tsawg kawg nkaus ntawm elongated, deformed hais nrog pores, slag los yog av yog ua tau.

Qhov no tsis cuam tshuam qhov kev ua tau zoo ntawm kev txhaj tshuaj, nws tuaj yeem lees paub los ntawm kev ntsuas nws qhov kev ua tau zoo ntawm lub tshuab.

HARDNESS

Lub bainitic microstructure lav qhov siab ntawm hardness.90% ntawm cov khoom yog nyob nruab nrab ntawm 40 - 50 Rockwell C.

Cov pa roj carbon tsawg hauv kev sib npaug nrog cov manganese lav lub neej ntev ntawm cov khoom, yog li txhim kho kev huv ntawm cov khoom, txij li nrog kev ua haujlwm txhua yam lawv nce lawv cov tawv tawv.

Lub zog ntawm kev txhaj tshuaj blasting yog absorbed tsuas yog los ntawm qhov chaw, yog li txo qhov hnav ntawm lub tshuab.

CARBON GRANULATION, Kev ua haujlwm siab

Kev siv cov roj carbon tsawg txhaj tshuaj muaj peev xwm rau cov tshuab uas muaj turbines ntawm 2500 txog 3000 RPM thiab ceev ntawm 80 M / S.

Rau cov khoom siv tshiab uas siv 3600 RPM turbines thiab ceev ntawm 110 M / S, cov no yog cov yuav tsum tau ua kom cov khoom tsim tau.